first i want to finish the master and them see what happens.

In this tutorial, nosotros will encompass all the MM views with the implication on vital processes in standard SAP system. You will see how each of the views is created, its obligatory information, optional fields, and how its creation reflects the organization. This tutorial is 7000 words+. For easy reference , we have created a clickable index below , which will take you to various sections of the tutorial

- Basic Views

- Classification View

- Sales Arrangement Data 1

- Sales Organization Data two

- Sales General / Establish View

- Foreign Merchandise / Export View

- MRP View 1

- MRP View 3

- MRP four View

- Plant data – Storage 1 View

- Warehouse Management i View

- Warehouse Management 2 View

- Quality management View

- Accounting 2 View

- Costing 1 View

- Costing ii View

- Purchasing View

- Foreign Trade Import View

- Buy order text View

- Additional data

Basic Views

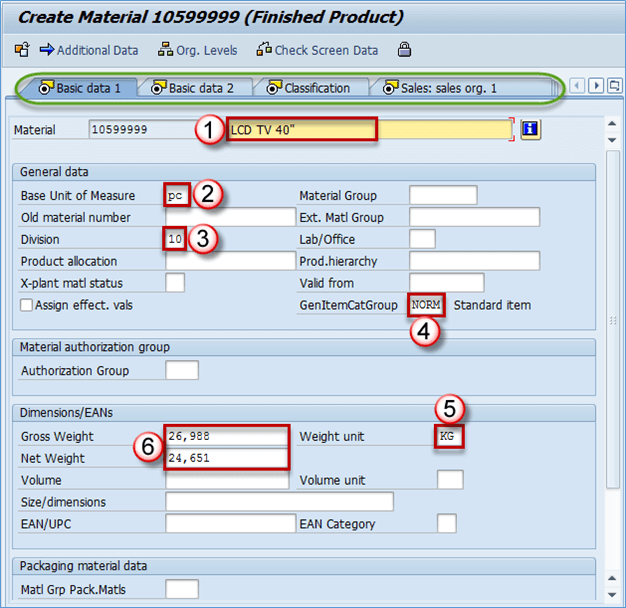

Basic views are views with full general data about our cloth. Obligatory fields you lot demand to insert in order to save changes are

- Cloth description: LCD Tv 40″ – this can be maintained in various languages.

- Base of operations unit of mensurate (frequently referred to as Base UOM): PCS – this is the unit of mensurate in which fabric stock is managed. For a Tv set, it'southward natural to be a piece. You can besides use meter, kilogram, or whatever other unit of measurement you take defined and is suitable for textile.

- Segmentation: 10 – Division for the material, you could create divisions ten, 20, xxx, 40 for finished goods, trading goods, services, and other materials, then you can categorize them in this way. We have selected sectionalization 10 for our material since information technology is finished goods.

- General Item category group: NORM – Standard item. Used throughout the system, this indicator has an issue on sales and stock transfer processing as information technology is used in item category determination.

- Weight unit: Kg – unit in which product weight is entered.

- Gross weight: 26,988 – gross weight of ane unit of product in weight unit. Net weight: 24,651 – net weight of 1 unit of product in weight unit of measurement

Basic data – optional fields

Textile group – you tin enter cloth group here Production hierarchy – this field is used in sales and distribution and is maintained in Sales system 1 view. EAN/UPC – Material EAN lawmaking, besides usage in bar coding, it is particularly utilized in Warehouse direction as a unique identifier for material and package combination. Ane cloth tin can have several bar codes. I for the base unit of mensurate. Every alternative unit of measurement of measure can as well have it's EAN, just it's not a requirement, it's an option. Other fields are optional. Notation:In the upper part, (marked in dark-green) you lot can see views that are possible to maintain for current material. You can navigate by clicking on the appropriate view name.

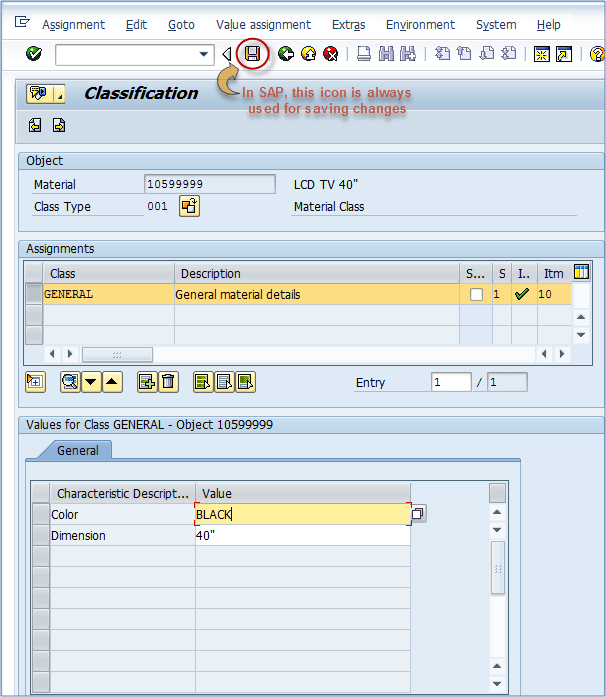

Classification View

Materials tin exist classified in guild to be establish after past their course, batch characteristics etc. Allow'southward say we have a lot of Tv set sets with different dimensions colors etc. You tin create two classes: dimension and color. Later y'all can employ it to find all the blackness TV sets, or TV sets of a sure dimension.

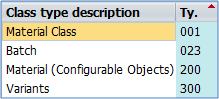

Form types bachelor in standard SAP

By choosing Cloth Class – 001 you are extending material for this form type. Now we have to add a class nosotros desire to use for our material. A form called Full general could consist of two characteristics: Color and Dimension, or annihilation that yous might need while categorizing materials or searching them in MM module, or other modules. After class assignment to the cloth, you tin maintain characteristics that this class contains. In our example, we have a class named General that contains characteristics Color and Dimension . Nosotros can populatethe appropriate fields.

Assigning a class and maintaining values for characteristics

It is a good practice to include the color of your production in textile description as well; it is extremely useful to other users. For instance while creating sales orders in SD, for picking and putaway processes in warehouse management, purchasing department, production planning etc. You can at present save your changes.

Saving Classification view

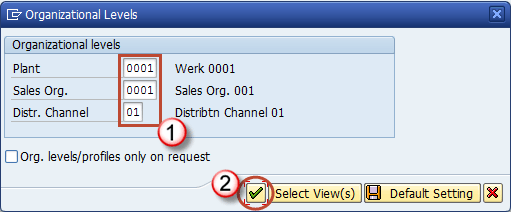

Sales System Data 1

When you choose this view, a screen with organizational levels will appear. Here, yous can cull for which Found, Sales arrangement and Distribution aqueduct yous want to extend your material.

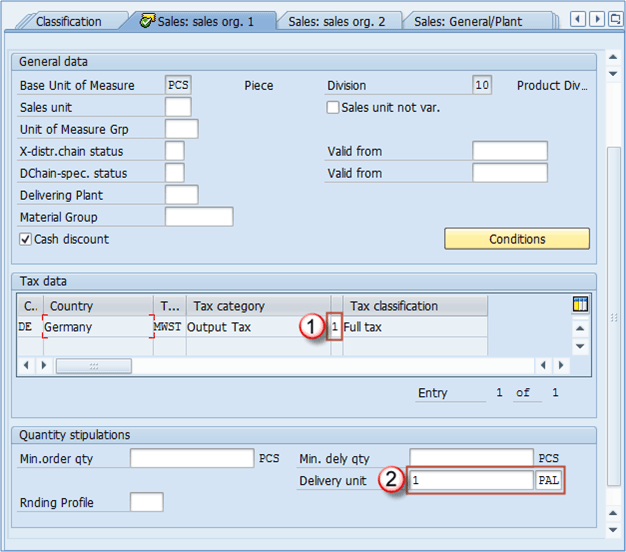

After confirming Organizational Levels, you are presented a screen which contains the data regarding sales activities. The but mandatory field is the delivery unit of measurement. Others are optional, merely they might be needed in gild to employ some advanced features. For example, if you want to employ dynamic rounding contour (must exist customized by SD consultant), you have to maintain field Rounding profile. Allow'south notice out what are the most important fields in sales views. The most crucial thing about sales views is that they are open. When we exercise that people from SD module can sell our material through that Sales Organization / Channel. Then essentially you would but take to populate the Commitment unit field and salvage the data, and immediately cloth becomes bachelor to be used. To get a better agreement of Sales organization, think of it as an office that sells your products. In this office, yous have people that sell products in your dwelling house country – they are using distribution channel 01, and you tin have people selling abroad, export department that would be channel 02. On the screen below, yous can run across all of the fields from Sales organization 1 View.

Taxation category/indicator: For internal sales, we volition have to define a full tax indicator since the revenue enhancement is applied for sales within the country. For export, (using sectionalization 02 for example) nosotros would set this to 0 – No Revenue enhancement. It really depends on the tax policy of your country, simply well-nigh of the countries accept this practice I mentioned. Delivery unit of measurement: in well-nigh cases it's starting time alternative unit of mensurate (box, pallet, something else). Yous can see that here nosotros will define 1 PAL – pallet as a commitment unit of measurement, but that doesn't mean that we can sell merely entire pallet. We will also be able to sell a unmarried piece of this fabric, and the system will indicate to sales person that this material is meant to exist delivered equally 12 pieces on a pallet. Base unit of measure: this is grayed out field as it is already defined in Basic Data view one and cannot exist inverse afterwards. Division: this is the division we have just selected in our organizational levels screen before electric current screen. Sales unit of measurement: If the field does non comprise an entry, the organization volition assume that the unit of measure out is the base unit of measure. If you don't want to utilise pieces as a default sales unit of measurement of measure, you tin can enter the appropriate unit of measurement of measure in this field. It will reflect sales documents in this mode: – Sales unit is not defined. Sales person enters quantity of 4 without specifying unit of measurement of measure. System will assume that the required quantity is iv pieces – Sales unit is defined as pallet. System volition assume that the required quantity is 4 pallets Sales unit non variable: this check box is used in cases when we require the textile to be sold only in sales unit of measurement. If you ready the sales unit to PAL, and check this box, sales person volition only be able to sell this material using the PAL alternative unit of mensurate. This is existence used rarely. Unit of measure group: Used mainly in conjunction with dynamic rounding contour, this is an indicator which represents a group of units of measure that can be used for this cloth. Material grouping: cloth group nosotros discussed during the Bones Data view. Min.order qty: This is a minimal lodge quantity accepted for this material. Min.dely. Qty: This is a minimal delivery quantity accepted for this material. Rounding contour: Here you lot can cull a specific rounding contour for fabric. SD consultant has to create the profiles to be shown as possible entries in this field.

Sales Organization Information ii

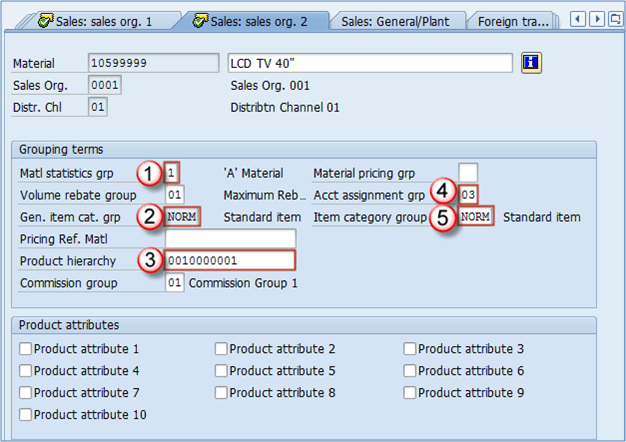

With same Organizational Levels, nosotros tin can create the sales organization data two View and maintain its data. By and large statistical and grouping data are subject of this view.

Important Sales System Information 2 View fields

- Material statistics grouping: This is an indicator used to specify if this material is to be included in statistical transaction in SD module MCSI. It is most used to ready this indicator to 1 in well-nigh systems.

- Full general item category group: default item category group for this cloth based on fabric type settings. You cannot change information technology.

- Product hierarchy: This hierarchy is used for reporting purposes so that sales management can analyze sales data based on this hierarchy. It consists of two levels. For example, first level of hierarchy could be LCD TVs. Within the first hierarchy level, nosotros tin find more than one second level, and in our case, we can take LCD TV xl″, LCD TV 32″, LCD Tv 26″ within our first level which is LCD TV. Another level would be Plasma Telly. In this first level, we tin can maintain Plasma Television 22″, Plasma TC 32″, Plasma Television twoscore″. Every first level of bureaucracy contains unique second level hierarchies.

- Account consignment group: this field represents the Accounting requirements for the material. Often unlike types of materials crave different Accounting requirements (finished goods, trading goods, services aren't accounted in the same way). This is a indicate of integration with FI/CO modules.

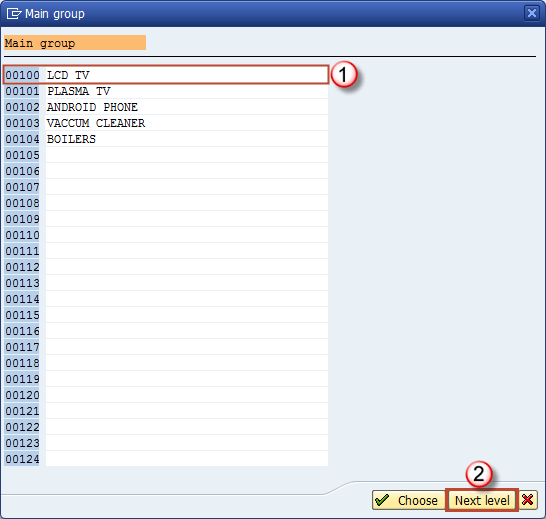

- Item category group: information technology's copied from 2- General item cat.grp field, but this is the category group that is assigned to specific distribution aqueduct. It tin can be changed equally opposed to the field no.two, and with this field yous can manage how will the same textile will be used in sales in different channels. For example, you might want a material to have dissimilar item category in strange sales activities than the default. It is changed mainly under directives from SD team. Production hierarchy – choosing the appropriate hierarchy from a predefined listing: Yous have probably already idea how product hierarchy is hard to maintain. You simply come across a bunch of numbers. Information technology's hard to know which numbers are advisable fo detail textile. Besides the fact that this is the information that sales & distribution team should supply to y'all, at that place is an easy manner of browsing through all of the hierarchies. When you push the push button that shows you possible entries for a field you go to this screen:

First level of hierarchy

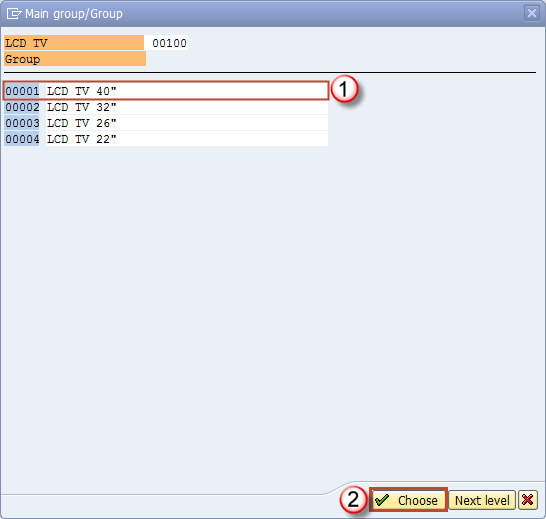

After selecting the appropriate first level, you should click on Next level push merely as on the above screen. Yous will be taken to the screen with possible entries for 2nd level of bureaucracy. As yous can see in the header of this screen, at that place is an indication that this second level of hierarchy is for a first level 00100 – LCD TV:

Second level of hierarchy

Last issue is as on the screen below:

![]()

Product bureaucracy on Sales Organisation Information 2 View

Other fields in Sales organization Data 2 View Book rebate grouping: grouping used for rebate settlement, can be fix to maximum rebate, depression rebate, depends on settings in SD module, this data is supposed to be provided by SD team. Pricing Reference Material: textile principal tape that should be used as a reference for pricing purposes. Commission group: you can assign the same commission grouping to more material as long as the commission is the same for both (for example 5%). Material pricing group: used to group the material with the aforementioned pricing procedures. Later in SD condition record can be created based on this field, apart from standard ones (product hierarchy). You lot can combine material pricing group with the customer number to create a condition. Production attributes: you can assign various product attributes to a textile and bank check if the customer accepts this product attribute.

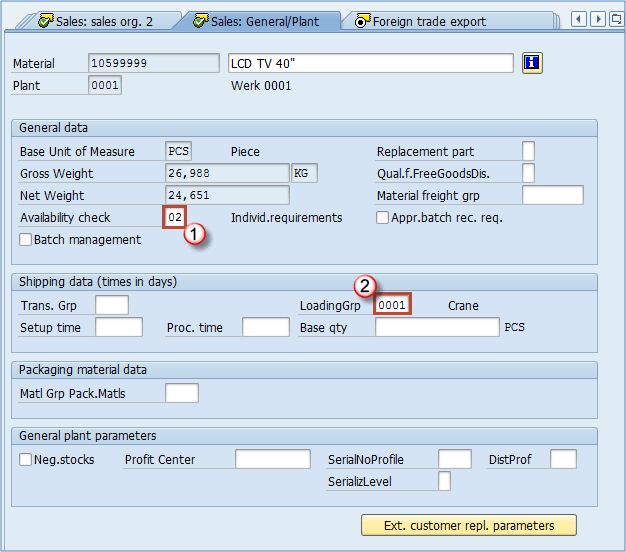

Sales General / Found View

This view contains information virtually full general sales characteristics of material. Information technology is maintained on Constitute level.

Mandatory fields

- Availability check: very essential attribute, used to define the stock availability check method. These methods are defined by customizing team, and can include stock on storage locations, can exist as well set to include quantities on process and product orders, planned orders, quantities in the transfer towards the found from which sales is beingness processed, etc.

- Loading grouping: extremely significant field as it is used in aircraft point determination. Optional fields in Sales – Full general / Plant View Replacement office: defines if this material is a replacement office or not. Material freight group: used for grouping materials in gild to be classified according to freight lawmaking and grade. Batch management: Indicates if cloth is managed in batches or non. Approved batch tape required: determines if batch approving must be submitted before the batch can exist transferred from restricted to unrestricted stock. Transportation group: a way of group materials with same transportation needs. It is used in SD module for route scheduling in sales orders and deliveries. Example: when you have materials that require to exist transported carefully equally they are fragile, and others are non. Setup time, Process time, Base of operations quantity: these iii fields are used to calculate fourth dimension consumed for shipping the material, the first is time in which you will ready devices for shipping, 2nd is processing fourth dimension per base of operations quantity (third). Fabric Group – Packaging Materials: this field is used for grouping the materials with similar packaging materials requirements. Negative stocks: If you check this box y'all will allow negative stocks for this material in this plant. This requires also a setting past your MM consultant on storage location level (in customizing). Profit heart: assign an adequate profit center for the material for controlling module purposes. This means that profit made from this textile will be assigned to the profit center gear up in this field. For instance if this is a finished product that makes a profit by sales you might want to choose a profit center for sales revenues. It also depends on management conclusion. Management might prefer to use another cardinal for profit centre accounting. Serial number profile and Serialization level: these control serialization of product (if you accept information technology active), a contour used for the serial number, and serialization level that could be by material number etc. Distribution profile: signals where the incoming (procured) merchandise will be distributed in our plant.

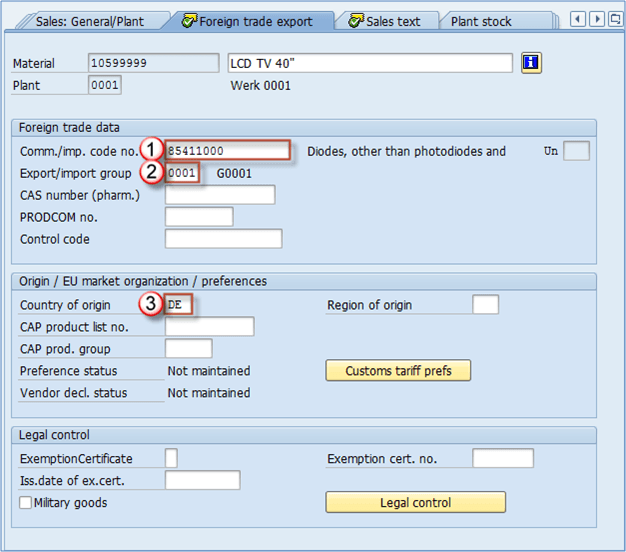

Strange Trade / Export View

This view contains information about freight, foreign trade, exporting of materials.

Mandatory fields in this view are:

- Commodity Code/Import Code Number for Foreign Merchandise: This field contains either a commodity lawmaking or a tariff number. It is a unique standardised coding value for a sure type of goods.

- Export import group: system can apply export/import groups to advise an consign process for consign/import processes in SAP.

- Country of origin: it represents the country where this material has been produced. If it's finished goods produced in-firm y'all volition enter your state lawmaking hither (in our example it is DE – Germany). Other fields All the characteristics for sales views are supposed to be provided by the sales department (sales, freight), the role of a fabric master specialist/user is merely to maintain them accurately. Some other information you tin can be given by your sales department to maintain in material master: CAS number: this field is only used for pharmaceutical products. PRODCOM no. – used only in European union countries for statistical purposes in product. Control code: Consumption tax control code in foreign trade. Region of origin: Besides country you can define a region in the country (for ex. Bavaria, Hessen etc.) CAP product list no. – this is the number of the material in the Eu market products group list – if applicative. CAP product group: indicates a product grouping from CAP product listing. Exemption certificate: indicating if the cloth has been issued a certificate that states that this material doesn't need a license for export. Exemption cert. Number: Number of the exemption document. Issuing engagement of exempt.cert. – Issuing date for an exemption certificate. Military goods: a check box indicating if the material is mainly used in military machine purposes.

Sales Text View

Yous tin ascertain a sales detail text for this material for diverse languages to be used in the sales documents. This could be some general caption about the material, or explanation maintained on distribution aqueduct level. If you maintain this text it volition evidence upwards on the item level in all sales documents, and also in the printing version of sales documents.

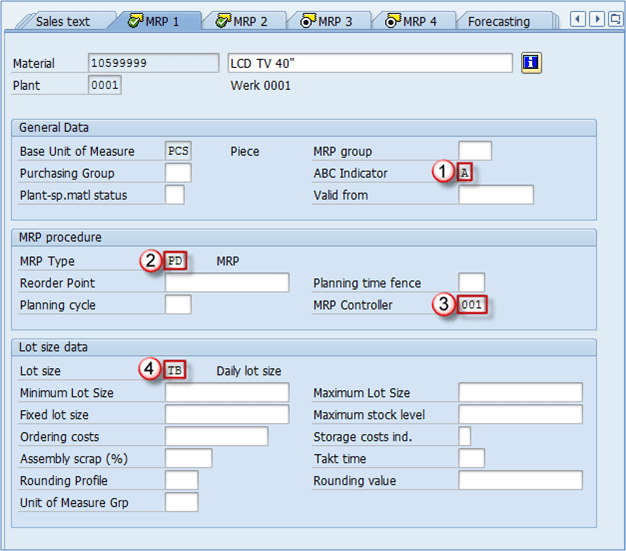

MRP View 1

MRP views are maintained mostly for production purposes. This data is supplied past the appropriate MRP controllor or someone else from product planning team. The only mandatory field in MRP i View is Planning type. We volition encompass the most important fields used in a productive environment in more detail.

Purchasing group: this field is used to indicate which purchasing group is the default for purchasing this material. We haven't maintained it all the same as this is a finished product of our company, we don't demand it to be purchased at any time. We will set this field for another cloth that needs to be purchased.

- ABC indicator: This is an indicator showing the importance of the material in terms of stock availability. Most of the companies use several ABC values, but most common are: A – the virtually important materials, they need to exist available for sales in every moment customer requests it, B – less important materials that are often supposed to be bachelor simply the lack of this material can happen and is immune, C – Least important materials. There tin can besides exist few more categories, N – new, material not however tested on the market, and so we don't actually know if information technology's going to be A, B or C all the same. S – fabric that is produced only on customer request, and D – aforementioned equally Due south with the difference that it has a sure quantity on stock simply in case someone needs it ASAP, in production planning it is chosen a material rubber stock.

- MRP type: there are diverse types of MRP that can be utilized. In this case, our MRP controller signalled that it should be PD – default MRP for well-nigh of the SAP installations.

- MRP controller: MRP controller responsible for production of this material, he manages all the data in these MRP views, along with the MRP results itself, product planning for this cloth etc. It is usual that the MRP controller provides the data for MRP views, or even in some organizational structures MRP controllers are maintaining these views on their own.

- Lot size: defines the procedure used by the system in order to calculate the procurement or production quantity of the material. Other fields in this view MRP group: this setting is used to grouping materials with same MRP control parameters which are, for example, the strategy group, the consumption mode, etc. If this field is non maintained, the system will apply material grouping from Basic Data 1 when performing the MRP. Plant-Specific Cloth Status: If set, this indicates the usability of material in special functions, for example, material can be used for Testing or is going to be discontinued, so the MRP doesn't take it into business relationship when it runs. This setting could restrict the use of material in a particular function. Reorder Point: indicates at which stock level MRP should create a new club (either procurement or production order). Planning bike: cycle of planning, it is defined in customizing and assigned to a material, it can represent a day on which the planning is performed. Minimum and Maximum lot size, Stock-still lot size: used to indicate the boundaries for lot size, or a fixed quantity to be used. Ordering costs: fixed cost per order in visitor code currency, used to summate the optimal lot size. Rounding Profile and Unit of Measure out Group: like the fields in sales views, these are the same fields you tin can populate with rounding type to purchasing or production (if applicative). Rounding value: it is used in procurement for rounding the procurement quantity to a value of multiple of the number entered here.

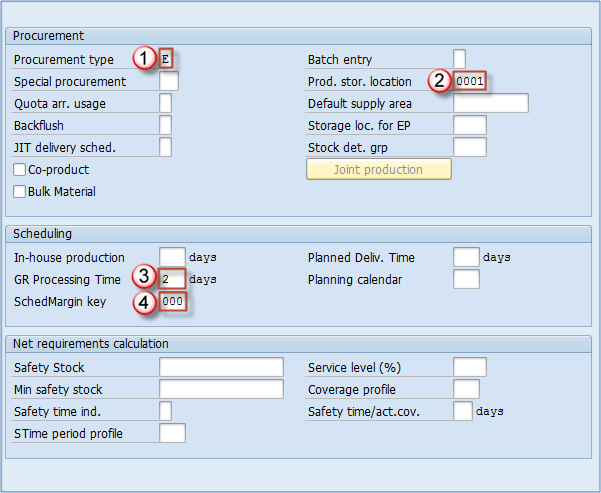

MRP View 2

MRP view 2 contains data about Procurement, Scheduling, and Net requirements calculation.

- Procurement type: here you can choose if your material has internal production (our case), external procurement, or both types of procurements are possible. It also mightn't have procurement at all.

- Production storage location: hither yous will maintain the storage location that is copied throughout the production documents. If this is a production component this marks the location from which the appurtenances issue is posted, or if information technology's produced material it annotates a location to which the cloth receipt is posted.

- Goods Receipt Processing Fourth dimension in Days: you can ready this value that represents needed fourth dimension in days for goods to exist inspected and placed into appropriate storage location.

- Schedule margin key: this represents a key used for conclusion of the floats required for scheduling an guild. It is divers in customizing and is supplied by your MRP controllor or PP administrator. Other fields in this view Special procurement: used to override the procurement type. Batch entry: indicates when the batch determination should be executed. Default supply area: if you lot define it this will be a proposed supply area for the material, information technology'due south more often than not used for KANBAN type of materials. Backflush: determines if backflush indicator is to be set in the production order. Storage location for external procurement: storage location to exist proposed in the purchase requisition. Stock determination group: this indicator along with the stock determination rule create a cardinal for the stock determination strategy Co-product: if checked, indicates that this fabric can also be used as a co-product. Bulk material: this identifies a pecker of materials item as a majority material. This is important as requirements of bulk materials are not relevant for the MRP. Safety stock: quantity in base UOM to use every bit a safety stock. Minimum safety stock: Safety stock in never allowed to driblet beneath this value.

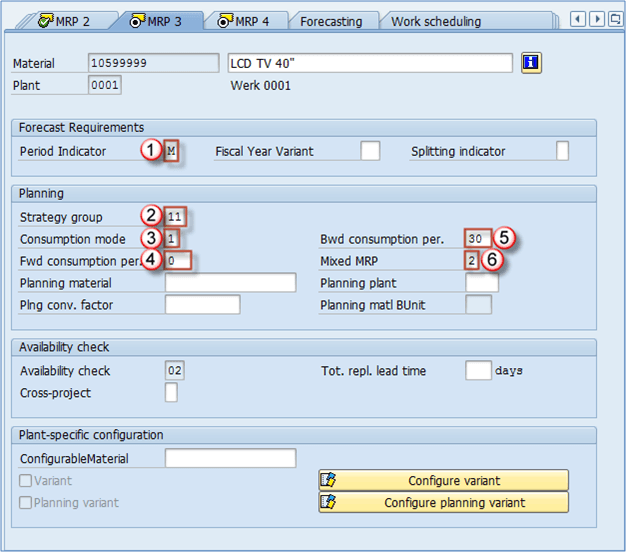

MRP View 3

MRP view 3 contains several valuable fields more often than not used by planning functions.

- Period indicator: indicates if material is to be planned/forecast monthly, weekly, yearly, daily etc. This is in most cases set to monthly.

- Strategy group: used for group the planning strategies, for instance, this can be gear up to Brand to Order, Brand to Stock etc. There are a number of options, and this must be defined past the production planning management. In most cases, fabric types and/or material ABC classification influences the decision which strategy grouping material should be assigned.

- Consumption manner: this controls how organization volition consume requirements. In backward mode sales, orders, dependent requirements or material reservations consume planned independent requirements that prevarication before the requirements appointment while in forward mode they consume planned contained requirements that prevarication after the requirements date.

- Forward consumption period: number of day used as a consumption threshold in forward consumption style. Can be set from one to 999 days only normally not longer than several days. We are using 0 since we are utilizing backward consumption mode for this fabric.

- Backward consumption period: Same equally previous except information technology is used for backward consumption mode.

- Mixed MRP: defines if material is available for subassembly planning and gross requirements planning.

Other fields in MRP 3 View Planning material: Only for use with planning strategy "planning with planning textile".

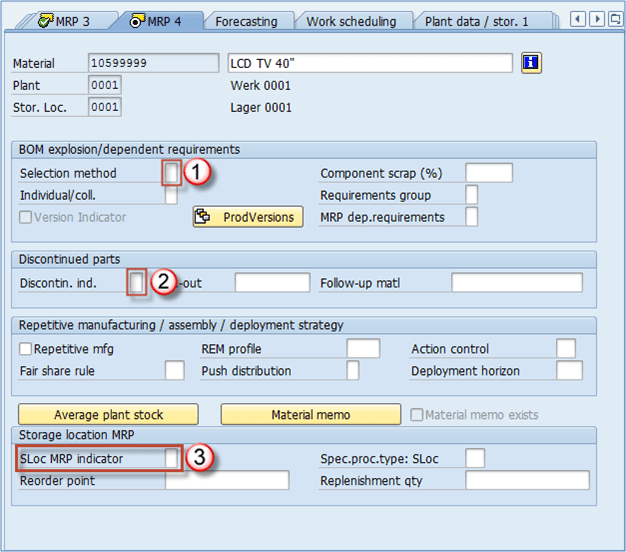

MRP 4 View

This is the just MRP view that is maintained on Constitute / Storage location organizational level. It doesn't contain as much valuable fields equally previous, but there are three handy indicators that tin be used to optimize processes in some modules.

- Pick method: if you are using BOMs (Bill Of Materials) for your production, you could govern with the option of alternative BOMs with this field. You can set up selection type by social club quantity, production version, explosion date.

- Discontinued indicator: you can select the indicator for discontinued function as per requirements.

- SLoc MRP indicator: this is the most powerful indicator on this view. It tells us if our storage location (that we used in organizational levels screen – in this example 0001 – Lager 0001) is relevant for MRP. That is highly significant as it can reflect not but MRP but too ATP (available to promise) quantities. For example, if we use the default value (empty field), it means that our storage location is taken into account in our MRP runs. It is also taken into account in ATP and so sales department can encounter the stock on this location available for sales activities. On the other manus, if you choose indicator 1 – Storage location stock excluded from MRP, this stock will not be taken into business relationship for the MRP run, also as it won't be bachelor to promise (ATP) to the customer, so it couldn't exist sold. If y'all choose indicator 2 – Manage storage location separately, it ways that yous want to manage this locations stock separately from constitute stock (useful in some rare cases). The most obvious example for usage of this function is rejects storage location. When our LCD Tv set 40″ comes out of the production line it can be fully functional, or information technology might accept a flaw. If information technology is ready for sales nosotros will transfer it to our 0001 location and sales section will see that quantity available to exist sold. Let'southward say nosotros produced 3000 Tv set sets. Out of that quantity there is 10 Television sets with some bug and our quality command department chooses that those cannot exist sold, then these are sent to our location 0003 for rejects. In MRP 4 view, we have to maintain the indicator 1 for our rejects location 0003 as we don't desire sales department to meet the stock as bachelor. We just want the other 2900 pieces available that are on the 0001 location, for which we maintain empty field for this indicator (include in MRP/ATP).

Piece of work Scheduling View

This view is used by the production to control the scheduling of production and process orders. A product schedule determines how chapters requirements are calculated for all the materials during a scheduling run. Here, you can as well activate batch management if material is to be handled in batches (certain quantities of material with slightly different characteristics). Batch direction can exist activated in several other views.

- Product schedule contour: define how the process will flow in PP or PP-PI, some additional controls about automatic goods receipt etc. Customized by your PP consultant.

- Underdelivery tolerance: define immune pct of quantity to be underdelivered.

- Overdelivery tolerance: allowed percentage for quantity exceding for production or process club. For overdelivering, you tin can bank check the unlimited box – in that case nosotros are allowing unlimited over delivery.

- Setup time: fourth dimension needed to setup and teardown piece of work center resources (lot size contained).

- Processing time: processing time for the base of operations quantity.

- Base quantity: used for processing and inhouse product time. In our case, processing fourth dimension is the time needed to process 48 pieces of our material.

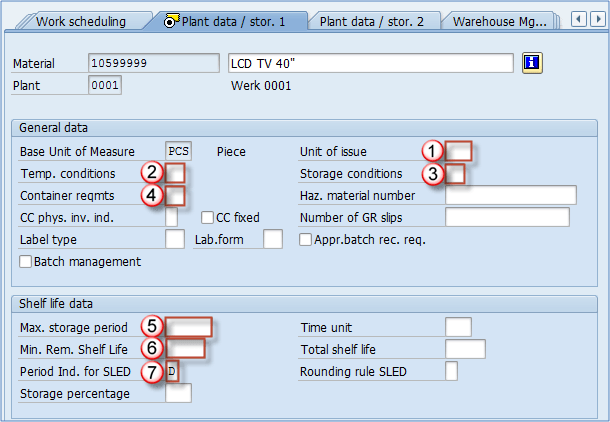

Plant information – Storage 1 View

Warehouse assistants team should supply the information for maintenance of this view. These are mostly storage data valid on the plant level. Let's go through all the essential fields for this view.

- Unit of issue: this is the unit in which material is issued from any storage location within the constitute (except for the warehouse managed locations which have a setting that overrides this field value).

- Temperature conditions: temperature (and atmospheric) conditions in which the textile must be stored.

- Storage atmospheric condition: storage conditions required by cloth.

- Container requirements: type, and weather in the container in which the cloth is shipped.

- Max.storage catamenia: maximum period of fourth dimension for which a material tin be stored.

- Minimum remaining shelf life: minimum remaining time for the fabric to exist allowed to exist stored (in case the remaining time is shorter than minimum – system will deny goods receipt).

- Catamenia indicator for SLED: used every bit a unit of time for Minimum remaining beat life. If this field contains D, than minimum remaining shelf life is maintained in days. Indicator M is for months etc.

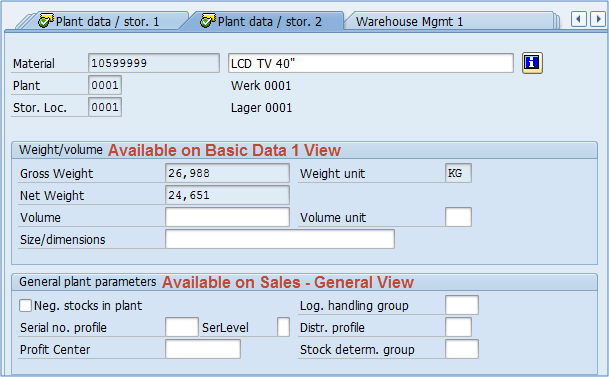

Plant data – Storage two View

These fields are repeating from Basic view ane (Weight/Volume section), and Sales – General (Full general Constitute parameters department), we had described them when we covered those views.

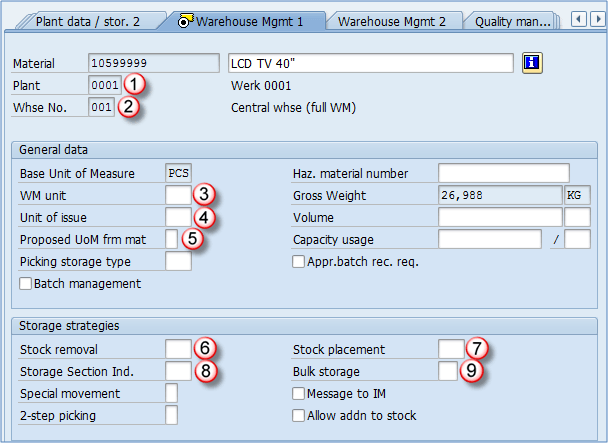

Warehouse Direction 1 View

This view is maintainable on Plant / Warehouse number organizational level. Warehouse number is the tiptop hierarchy level in warehouse management in SAP. You tin see positions ane & ii in the film beneath representing Plant and Warehouse Number for which we are extending the material. Information for maintaining this view should be supplied past warehouse management assistants team.

- Institute: organizational level

- Warehouse number: organizational level

- WM unit: unit that is used throughout the warehouse management. Every document in WM uses this unit of measure, no affair what is the original document UOM. For example, if you create delivery for 12 pieces of LCD TV twoscore″ and we take defined in warehouse direction view that WM unit is PAL, in transfer orders (WM document for stock management) 1 PAL will be shown instead of 12 PCS every bit the original document (delivery)item was created.

- Unit of issue: it is already covered in Plant Data – Storage 1 View.

- Proposed UoM for textile: this indicator determines which unit of mensurate should exist used in warehouse management in conjunction with WM unit of measurement. This indicator can be set to use Unit of measurement of Effect (divers here in material master), Lodge unit (unit of measurement in which the original document was created – sales order, commitment, reservation etc.), WM unit of measure, base of operations unit of measure, and some additional conditional possibilities (for case, if no other unit is specified use base unit of measure).

- Stock removal strategy: to be used, a stock removal strategy suitable for this cloth has to exist defined in customizing. For example, strategy for our material could be: starting time try to remove stock from high rack storage, and if there is no stock at that place effort picking from the bulk storage area. Used when we have to pick some quantity for customer (delivery) or reservation.

- Stock placement strategy: aforementioned equally above with opposite direction, when we want to place our stock from product to our warehouse, we want the system to search dissimilar storage types (areas) for placement in the warehouse. We desire the system to search in the right guild for this fabric so we can set up up the advisable strategy.

- Storage section indicator: when using indicators for stock removal and placement, we might encounter a problem that in the same storage type, we could accept storage bins that are smaller than usual and our fabric cannot be placed there. That is where we can employ storage section indicator, to instruct the system not to place our material in storage bins of certain department (smaller bins).

- Bulk storage indicator: this is used to indicate a special example for using up a majority storage type capacity. * Other fields include some special indicators, like special movement indicator, two step picking, allowing adding to existing stock in the storage bin already containing this material.

These settings are very complex and require more than in-depth knowledge of Warehouse Management.

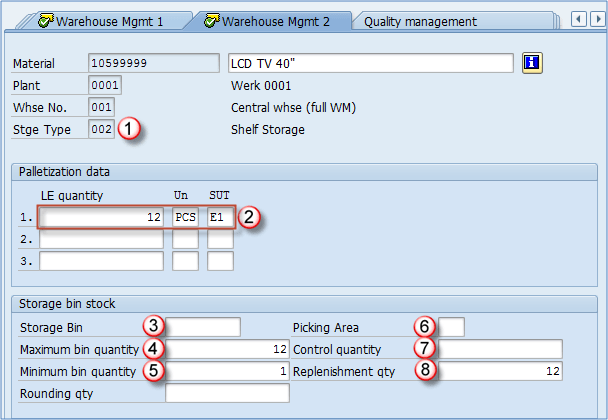

Warehouse Management ii View

This view is maintainable on one more level than the previous view. Here are located palletization data (quantities of material and types of pallets used) in the first section which isn't maintained on storage type level merely like previous view on warehouse number level. Lower section of the screen shows several fields that are storage type related settings.

- Storage type: the storage type for which we are extending/maintaining our material. In this instance, we desire our LCD TV to exist stored at shelf storage (we have already selected this strategy in WM i View).

- Palletization data: this is data about how our cloth is packed onto dissimilar storage unit types. For example, our cloth is packed 12 pieces on Euro pallet 1m high (divers every bit E1 in our organization).

- Storage bin: if we wanted to store our material in a predefined storage bin we would maintain this field. In this example, we want a system to suggest a bin for our fabric every fourth dimension we are executing putaway.

- Maximum bin quantity: this is usually a number that is maintained in palletization data, in our case 12 PCS. Used in check while placing the stock, system volition not let more than 12 PCS to be stored in ane bin. Warehouse Management ii View in material main

- Minimum bin quantity: this should be maintained simply if replenishment is active for the storage type (more often than not used in fixed bin storage types). In our case, if storage bin stock falls below i (no more than TVs in the storage bin) system would request replenishment to be made, to fill the storage bin with another pallet. This is a very complex topic and requires more in-depth noesis of warehouse management arrangement in SAP.

- Picking area: similar storage sections are grouping bins together in putaway process, picking areas group storage bins for picking process.

- Control quantity: for sure strategies (min/max quantity) utilized on storage type level, this is the quantity that signals the arrangement that if the requested quantity for picking is higher than defined in this field, system should skip this storage blazon and move on to the next in our stock removal strategy. This is used in cases where nosotros want to pick small quantities of material from one type of storage, and large quantities from another storage blazon.

- Replenishment quantity: when organization determines that replenishment of our bin is needed it volition furnish with quantity in this field. We have divers that we want replenishment when stock falls to nada, and we want it to be replenished by entire pallet – 12 pieces.

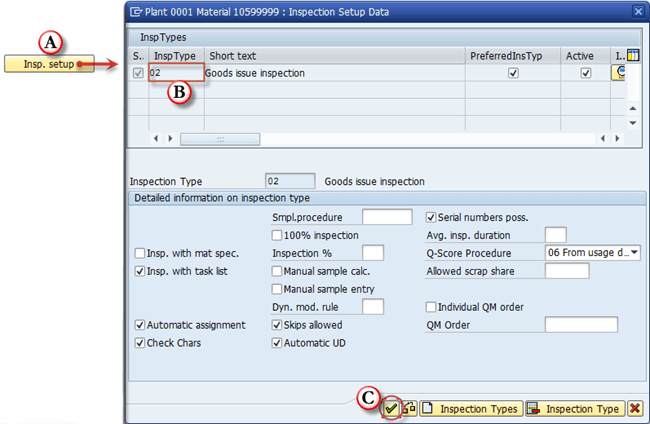

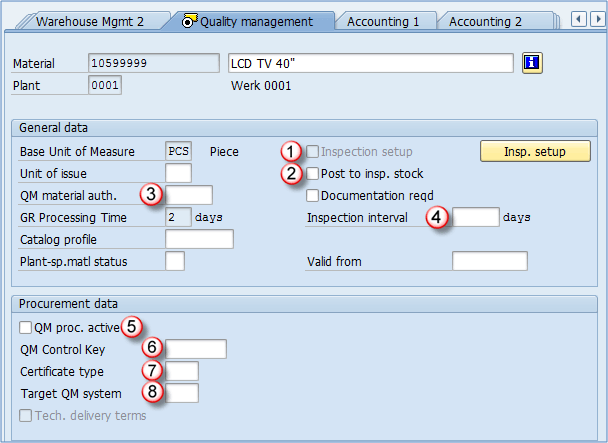

Quality management View

This view is used for material settings for quality inspection processes in Quality Management module. Administrators of that module are responsible for providing the data for maintenance of this view.

- Inspection setup: this indicates if at least one inspection type has been set upwards. In the setup itself, yous tin can choose the inspection type yous want to use for this fabric. Setup types have to be predefined by you QM consultant. Stride A: Click the Inspection setup button; Step B: choose the advisable inspection blazon predefined past QM team; Step C: confirm changes.

Choosing the inspection type on a subscreen of Quality Direction view

- Postal service to inspection stock: specify if the fabric is subject to quality inspection. If this is checked, an inspection lot will be created for the inspection blazon assigned.

- Textile potency grouping: you can define authorizations for QM users based on the authorization group, for example if you desire some materials inspected past some users, and other materials by other users.

- Inspection interval (in days): interval between recurring inspections for the aforementioned batch.

- QM in Procurement agile: activating Quality management for material in the procurement process.

- QM control key: used to define atmospheric condition in quality inspection in procurement. You tin can fix a delivery block, invoice block and other types of blocks until material inspection is done. Possible entries are predefined in customizing by the consultant.

- Certificate blazon: quality certificate type (possible entries are predefined in customizing by QM consultant).

- Target QM organisation: Required QM system by vendor. We specify if vendor needs to take ISO 9001 or other types of QM systems implemented and certified.

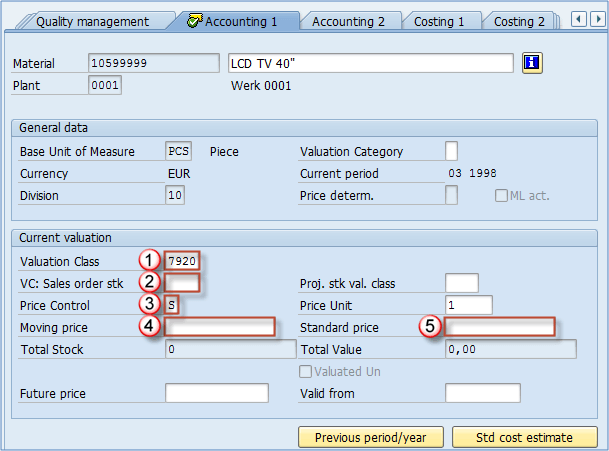

Accounting 1 View

Data entered in this view determines the manner that Accounting will exist processed for this cloth. Data is supplied by your FI/CO team, and groundwork customizing by your FI/CO consultant.

- Valuation class: depending on your organization settings, merely valuation class is in most times influenced by material blazon, so you will have a valuation class for finished appurtenances, and another for trading goods. In our case valuation class, 7920 is SAP default class for finished goods. For HALB, this class is 7900 by default, and for ROH we can use 3000.

- Valuation Class for sales order stock: you can assign a valuation class for sales social club stock to override the default valuation class defined in field i – Valuation Class. Non recommended.

- Price control: this indicated which blazon of internal price will be used for the fabric. It tin can be set to S – standard cost, or V moving average cost (variable toll). In most cases, S is used for finished goods while Five is used for trading goods, but the settings depend on your SD/FI/CO teams preference.

- Moving price: you tin can populate this field if price control is prepare to 5.

- Standard cost: you can populate this field if toll control is set to Due south. Your controlling team tin can use transactions for generating these prices based on the information contained in production orders, purchase orders, so that these prices don't accept to exist entered manually for each material. Nosotros tin can too maintain Valuation Category field, which determines whether stocks of the material are valuated together or separately.

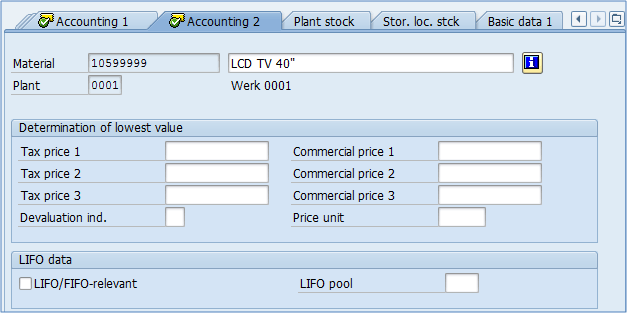

Accounting 2 View

This view isn't used very ofttimes in production environment, the virtually common setting for this view is leaving all the fields empty. Basically, it consists of special revenue enhancement data in Accounting which is hardly ever relevant. Conclusion of the lowest value of the cloth, cloth devaluation through it's status (moving, slow moving) etc. If this view is being used by your financial Accounting department, the section should provide yous the information for maintaining this view.

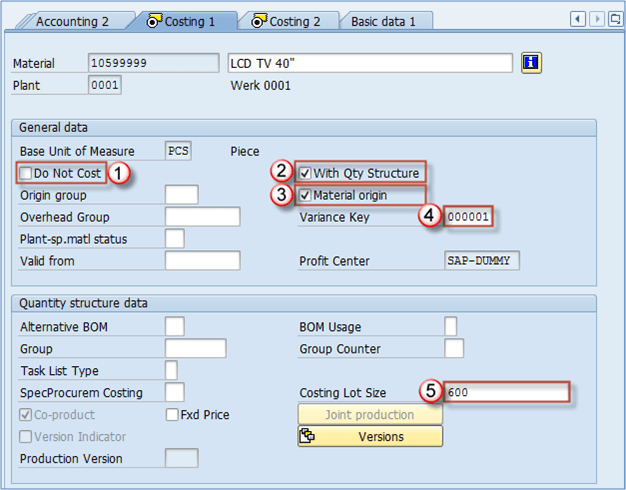

Costing 1 View

Costing view is used to determine the product price. It tin can take various inputs, but for production the virtually of import is the costing lot size. That means that an optimal lot size used for product toll estimate can exist set here. Production can be produced in a 100 pieces lot or in a 3700 pieces lot; therefore the costing for those two situations are unlike. That is because there are some fixed expenses (time for setting up appropriate tool, mechanics work. In the first case, our product price might be as high as 126 USD/pcs while in the other case, it could be 111 USD, which is remarkably dissimilar, and then production has to try to plan their activities and stock levels of all materials in a plant in a way that our product lot size doesn't vary also much and be as close to our optimal lot as possible.

- Do Not Price: no costing is estimated. Neither textile cost nor sales society cost is created, merely as procurement alternatives tin't be created as well. If you desire costing at all, leave the field blank.

- With quantity structure: indicates if we want to utilise quantity construction data for toll estimating (lot size and other quantity information).

- Material origin: this indicates if material number should be assigned to cost element item in CO module.

- Variance key: determines how price variance is calculated.

- Costing lot size: it is merely useful if cheque box "With Qty construction" is checked. It determines the lot quantity used for a cost judge calculation.

Costing 2 View

In figure 1 – Valuation data, we can see fields already covered in previous views (Accounting ane view). Other than that there are fields to maintain planned prices (Standard cost estimate will be copied to Planned price if standard cost estimate is checked and created).

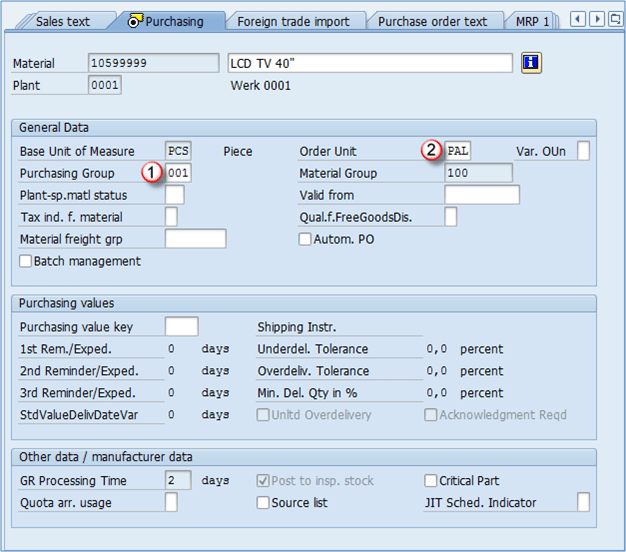

Purchasing View

In purchasing view, we can find several fields already present at previously covered views similar Freight group, plant special material status etc. We also have few new fields bachelor only from Purchasing view.

- Purchasing grouping: you can define various purchasing groups like raw material purchasing, trading goods purchasing, service purchasing etc. This value volition be the default value for all the items entered in purchasing documents.

- Club unit: default unit used for ordering this material. We accept used pallet every bit default so if we enter a quantity of 10 it means we are requesting 10 pallets of the textile (120 pieces in this instance). Y'all can encounter the Purchasing values section in this view. The only field you take to populate is the Purchasing value central which is maintained in customizing consisting of all the values you tin see in this section (underdelivery tolerance, overdelivery tolerance). When yous ascertain the key in customizing, the values from the key are transferred to all the fields in this department.

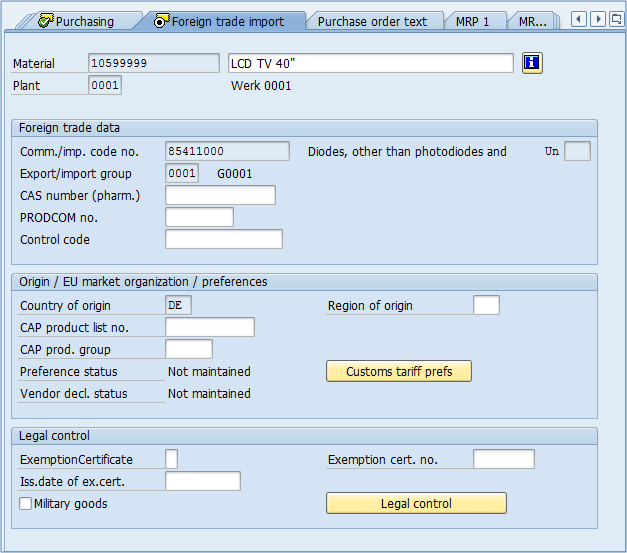

Foreign Merchandise Import View

Exactly the same view as a foreign trade export view.

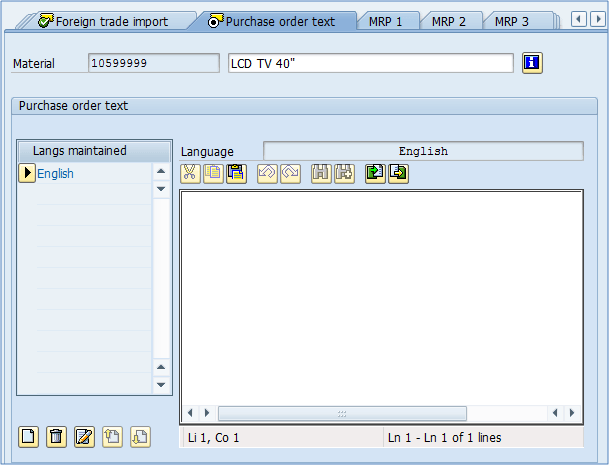

Purchase club text View

Exactly the same view as a sales social club text view.

Additional data

Besides material principal views, we take another level of maintenance in MM01 transaction. Information technology is besides with no reference to organizational levels. From any View in material primary you lot tin choose button Additional data:

Push button for switching to additional information maintenance

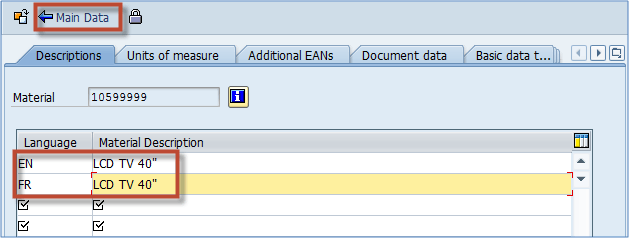

Once selected, you tin can see that we tin can return to MM Views by clicking on Main Data button.

Product descriptions for various languages in additional data

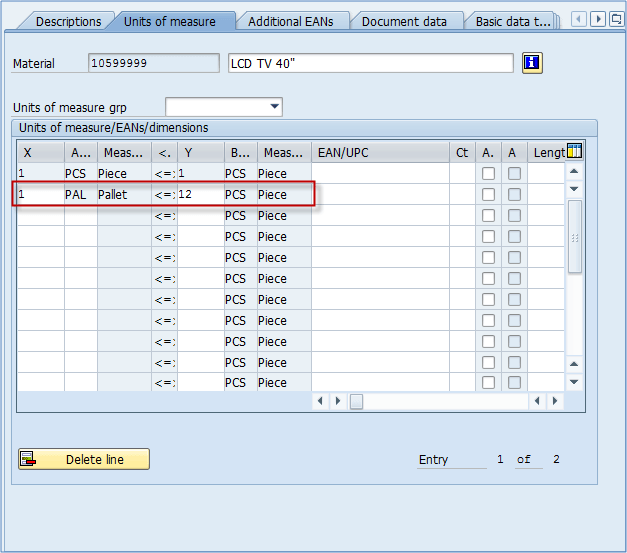

First tab in additional data is most cloth description. Y'all saw that we have already maintained textile description on Bones View 1, merely we accept only defined a clarification for the default language (logon language for user in this session). In boosted information, we can define descriptions for whatever other language needed. For example, I take created description for French linguistic communication. In our case, textile description is the aforementioned for both languages (in other cases you might need to interpret the clarification). This is of import because if you take a client from France and they are accepting only french product proper name, you have to define it here, and set advice language for that customer to French (this is done in SD module and is a point where integration between MM and SD is utilized). Maintenance of alternative units of measure out is utilized in the second tab. You can see that there is a record for 1 PCS, which equals to 1 PCS, and this is a record for our base UOM. The other i is ane PAL equals 12 PCS – it ways that our company packages LDC TV sets 40″ in the amount of 12 pieces on a pallet. You lot can add as many alternative UOMs as you like, equally well as delete them by using the Delete Line button. Here, yous can also maintain all EAN codes for all units of measure. In SD module, you lot can create sales orders by any unit of measure maintained in material principal. So practically it'due south the same creating sales order for 12 pieces, or 1 pallet.

Source: https://www.guru99.com/material-master-views-ultimate-guide-2.html

0 Response to "first i want to finish the master and them see what happens."

Post a Comment